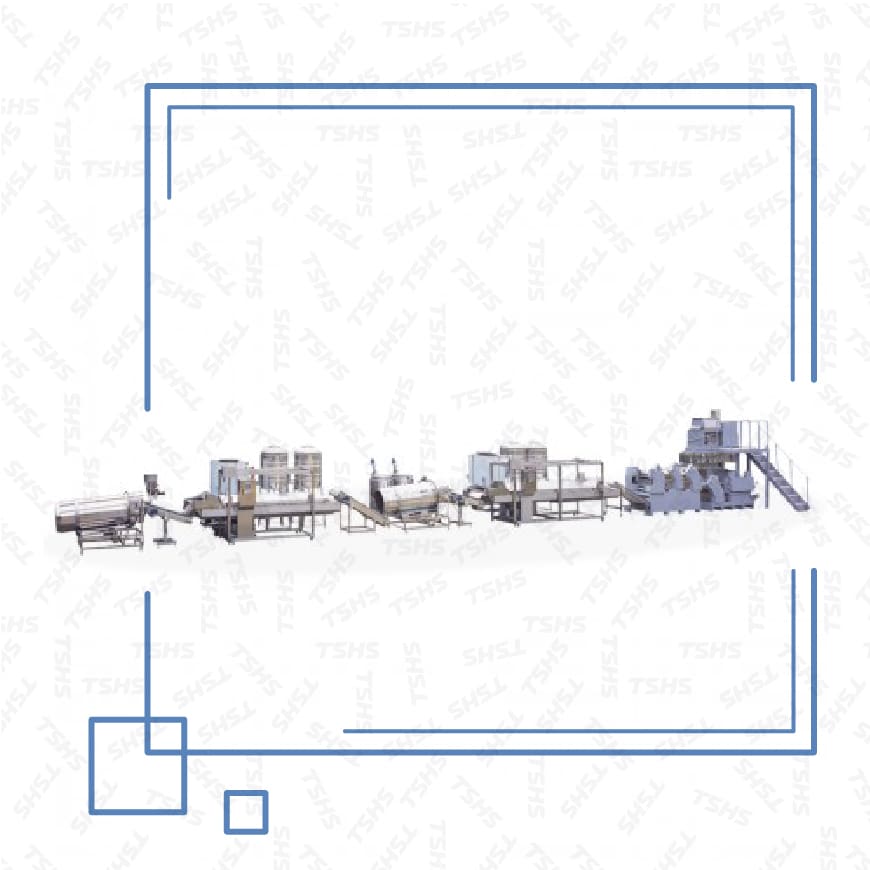

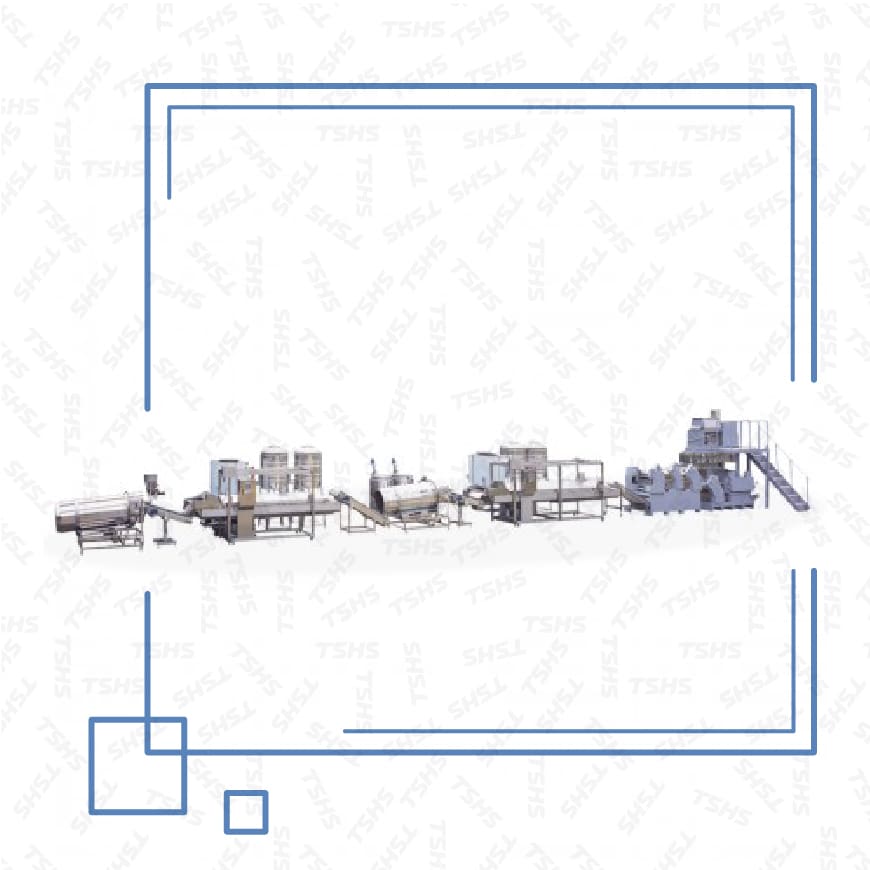

NOODLE SNACKS PRODUCTION LINE

TSHS-NS-300、TSHS-NS-500

Fried Noodle Snack Production Line

Noodle snakes (also known as snack noodles) are the bulk of the snack food market in Asia. Using the simple raw material - flour, which is easy to obtain around the world, mixed with water and other raw material to stir into dough, then stretched into crust, cut with a knife, and after frying and seasoning, it can produce the snack foods which are suitable for all ages and delicious. For casual food, the most common are fried noodle snack and crispy noodles. Among the long-term products in the Taiwan market, the most famous one are the “everyone says GOOD GOOD EAT” series products of Wei Lih Food company; In Japan is the Baby Star Crispy Noodle Snack of OYATSU company (ベビースターラーメン); in Malaysia is the New Star company's brand Snek ku is also quite popular; in the Thai market, the fried noodel snakes were made into the shape of chicken legs, let the word chicken leg (ขาไก่) become a synonym for fried noodle snakes in Thailand.

TsungHsing Food Machinery provides an automated, high-quality noodle snake production line is safe and hygienic, and can be produced easily and quickly.

The production of noodle snakes varies from country to country depending on the size of the product and the way it is seasoned. The basic configuration of the production line of noodle snakes is mainly composed of the following seven machines: raw material mixer, rolling machine, stamping machine, strip/ piece cutting machine, continuous frying machine, seasoning equipment, and cooling system.

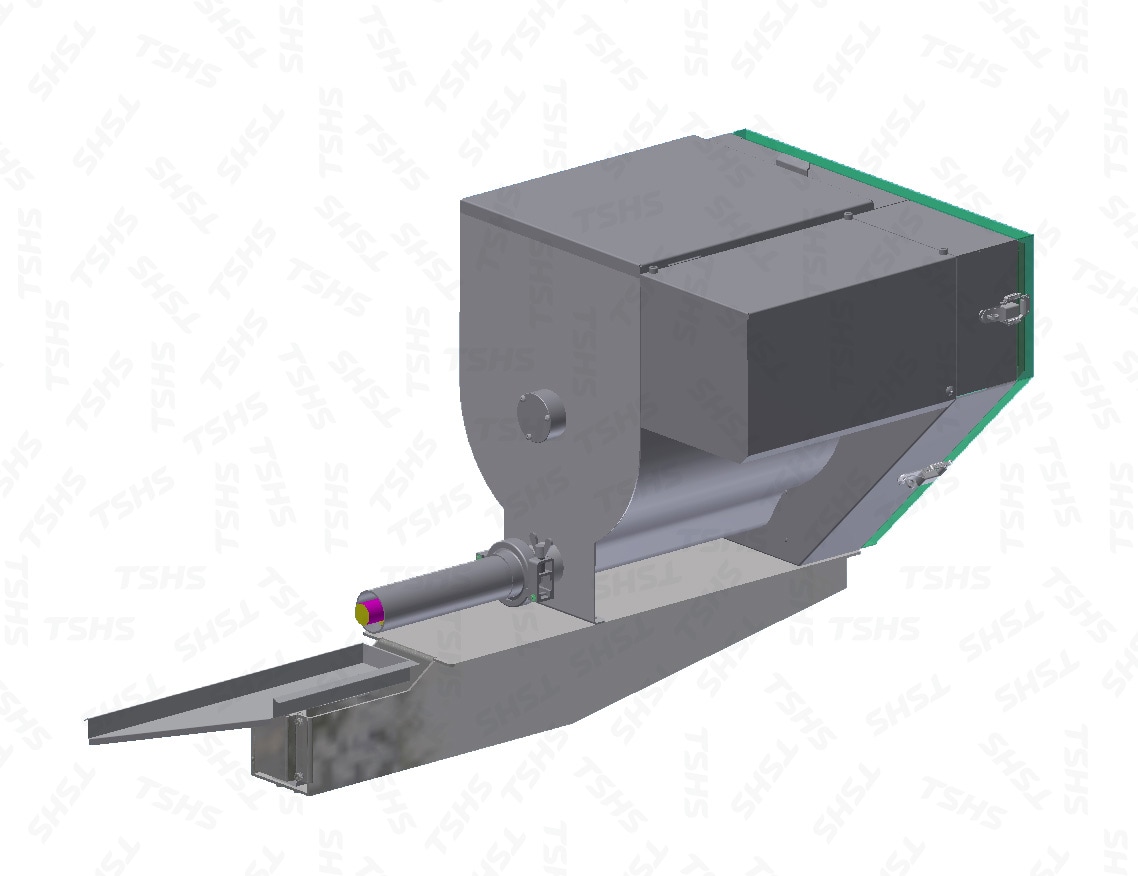

1. Raw Material Mixer Machine

Raw material mixing is the first step in the production of fried noodle snakes. The raw material mixer stirs the flour, water and other auxiliary materials into dough according to the manufacturer's formula. Then adjusts the dough's tendon and uniformity, and ensures the smooth rolling process to meet the required taste of the product.

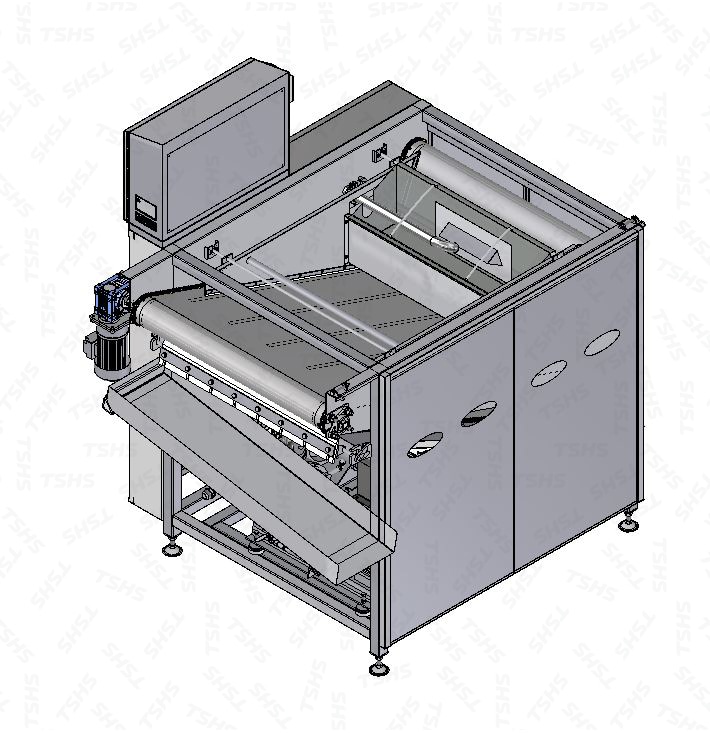

2. Rolling Machine

The rolling stage is to further extend the dough strip. The rolling machine makes the formation of the dough and the water distribution more uniform to facilitate the forming; at the same time, the thickness of the product is determined, which has a key influence on the subsequent process. It will then enter the stamping stage of the fried noodle snack production line.

3. Stamping Machine

The stamping stage provides stamping to the type and shape of the product desired by customers. Due to the different cultures and habits of each region, the stamping equipment of the fried noodle snack production line of TsungHsing Food Machinery can be adjusted according to the market trend and characteristics of the products to make the shape that meets the needs of customers.

4. Strip/ Piece Cutting Machine

Rolling determines the thickness of the product, stamping determines the shape of the product, and the strip/ piece cutting stage determines the length and width of the product. The noodle snake production line can change the width of the product by the replacement of the strip cutting knife, and the piece cutting knife is below to transverse cut the noodles, and then the length of the product is changed by adjusting the speed of the knife. The faster the cutting speed is, the shorter the product length is, and vice versa.

5. Continuous Frying Machine

Frying is a very important stage in the production of noodle snack. The temperature must not too high during frying. Avoiding such a situation just like making the surface of the product become brittle, but the center is not fully matured due to the excessive oil temperature. The continuous frying machine provided by TsungHsing Food Machinery can keep the frying temperature stable and ensure the first-in-first-out of the product through the continuous conveyor to achieve consistent and stable frying time and avoid material accumulation. The continuous frying machine of TsungHsing Food Machinery has the high additional value includes energy-saving, space-saving and oil-saving; it improves the heat exchange rate and recovery rate; the fully automatic control system can also save the staff's operation time and reduce the cost of production for customers.

6. Seasoning Equipment

The fried noodle snack production line is equipped with seasoning equipment, and both of the seasoning time, the amount of powder can be controlled. Customers can adjust at any time according to production needs. The seasoning equipment meets the safety and hygiene requirements of food machinery, and is formed by seamless plate, and the weld bead is polished to simplify the cleaning and maintenance process of the equipment, to reduce the cost, and the customer does not have to worry about the safety and hygiene issues, maintain the production process in a safe and stable state.

7. Cooling System

In the fried noodle snack production line, the cooling conveyor of TsungHsing Food Machinery adopts axial-flow fan and uses exhaust cooling instead of air cooling to meet food hygiene, avoids dust problems, and has excellent cooling effect, which can lower the product temperature in a short time. In order to shorten the waiting time for packaging, the product can be packaged and shipped faster.

CAPACITY

- Fried seasoning products: 300 kg / hour, 500 kg / hour.

- (According to the needs of customers.)

FLOW CHART

Raw Material Mixing → Rolling → Stamping → Strip/ Piece Cutting → Fryer → Seasoning → Cooling.

(According to the needs of customers.)(This is the basic configuration, please contact us for other special processes.)

FEATURES

- Raw materials are easy to obtain.

- Popular taste.

- Stable quality.

- Large output (300~500kg).

- Easy to produce with high additional value.

- Automate production lines and save manpower.

- Consistent operation, safe and hygienic.

- Changeable shape by replaceable blade.

- Easy to clean and maintain.

PRODUCT FEATURES

- After the flour, water and other formulas are stirred into dough, they are cut into the preliminary shape of the fried noodle snack by compounding, rolling, stamping and strip/ piece cutting, and then fried the product to a crispy taste, and seasoned, and the product is cooled before proceeding. Packaging to maintain product yield, stability and quality.

Specifications

1. Automatic Cracker Making machine

Specifications: Match according to requirements.

Horsepower Requirements: 43HP.

Yield: 300 kg / hour, 500 kg / hour (flour).

Features:

(1) Inverter control speed regulation.

(2) Adjustable shape of the product.

|  |

2.620D Continuous Oil Fryer

Specifications: Length 5890 ⅹ Width 820 ⅹ Height 55 mm.

Oil Using: About 850L.

Features:

(1) Continuous frying production, maintaining frying temperature and product quality.

(2) Automatic cleaning system saves cleaning time and manpower.

(3) Automatic filtration and slag removal, increasing the use time and save the cost of oil.

|  |

3. Seasoning Conveyor

Specifications:

Length 1500 ⅹ Width 850 ⅹ Height 1200 mm.

Conveyor Width: 350 mm.

Horsepower Requirements: 1/4HP.

|

|

4. Double Barrel Liquid Sprayer

Specifications: Length 2100 ⅹ Width 1150 ⅹ Height 1570 mm.

Horsepower Requirements: 2 1/2 HP.

Features:

(1) The internal heating and insulation system keeps the seasoning liquid into a liquid state, which is convenient for seasoning.

(2) Adjusted liquid spray amount.

(3) Controlled Pressure.

|

|

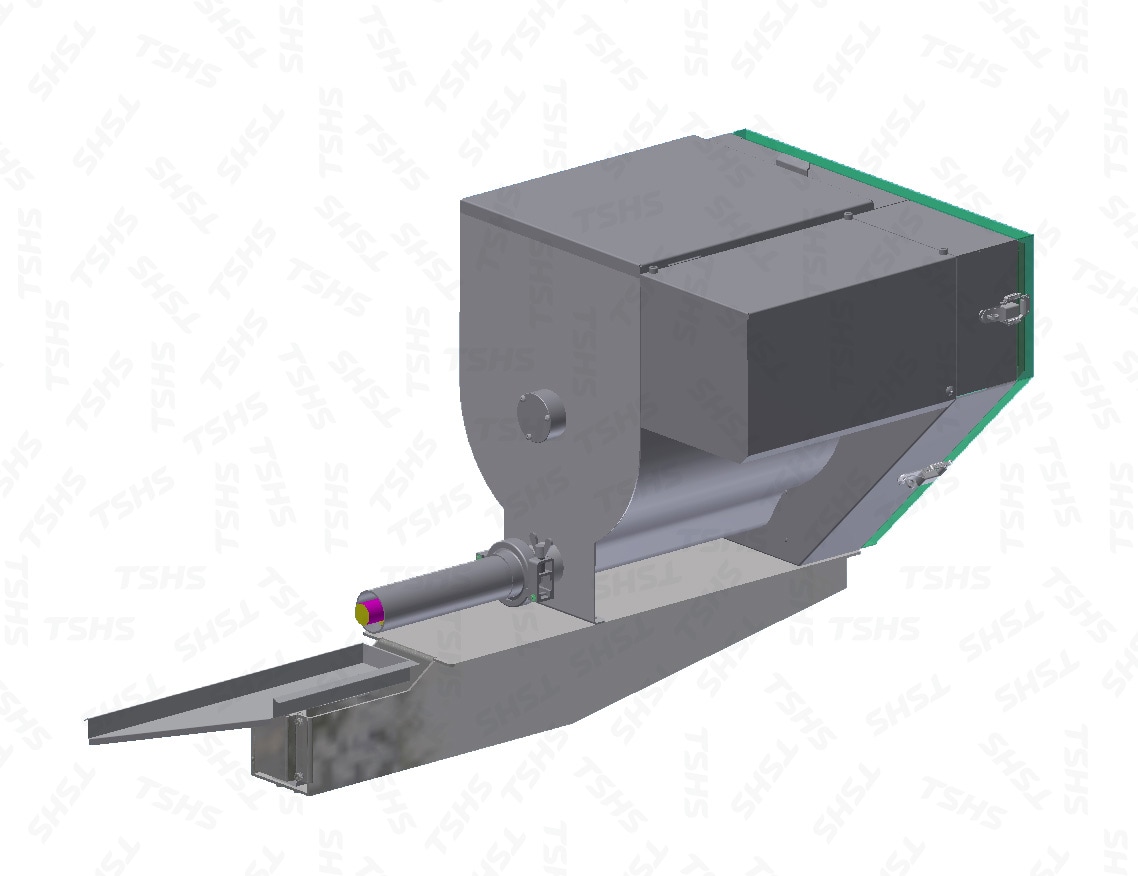

5. Vibration Powder Sprinkler

Specifications: Length 1610 ⅹ Width 630 ⅹ Height 1570 mm.

Axial length of powder sprinkling: 1M.

Features:

(1) The amount and speed of powder feeding can be adjusted according to the needs of customers.

(2) The way of sprinkling powder is similar to the large-width feeding method of waterfall.

|  |

6. Rotary Seasoning Drum

Specifications:

Length 2100 ⅹ Width 1100 ⅹ Height 1800 mm.

Features:

(1)Rotary speed is adjustable according need. Adjustable drum angle to control coating time.

|  |

7. Discharge Conveyor

Specifications:

Length 1500 ⅹ Width 850 ⅹ Height 1200 mm.

Conveyor Width: 300 mm.

Horsepower Requirements: 1/4 HP.

|

|

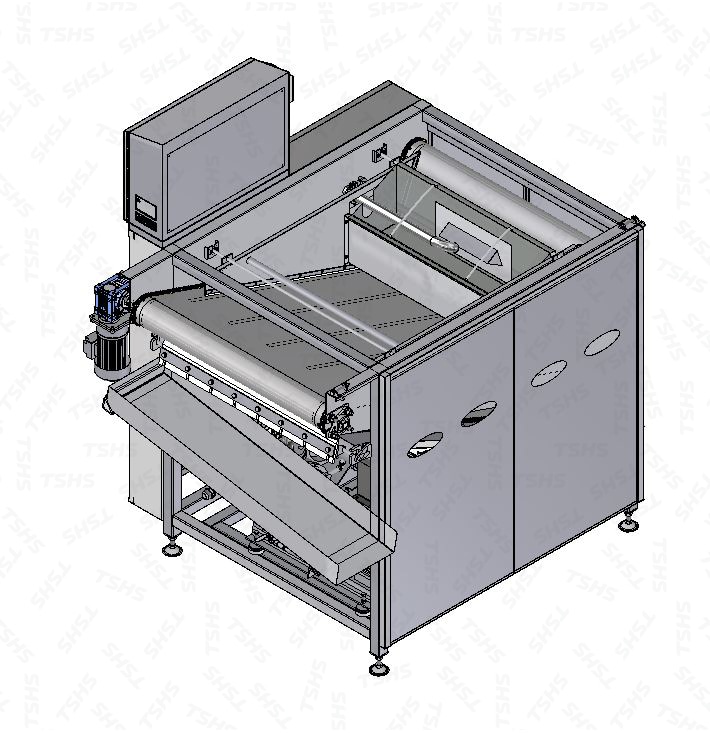

8. Cooling Conveyor

Specifications:

Length 5000 ⅹ Width 1500 ⅹ Height 1400 mm.

Horsepower Requirements:

2HP conveyor motor and 5HP axial fan.

Features:

(1) Cooling time can be adjusted according to the needs of customers.

(2) The fan can be controlled independently.

|

|

APPLICATIONS

- Noodle Snack Production Line

- Snack Noodle Production Line

- Radish Cake Production Line

- Winter Bamboo Shoot Cake Production Line

Peripherals / Accessories

Fine Filter

Specifications:Length 1750 ⅹ Width 1410 ⅹ Height 1760 mm.

Conveyor Width: 970 mm. Horsepower Requirements: 1/4 HP.

Filter effect can be achieved 80Mesh, to ensure the quality of the filter.

|  |

Mechanical Flowchart

Contacts us

Phone:886-7-6166555E-mail:machine@tshs.com.twAddress:No. 669, An Jao Road, Yen Chao Dist., Kaohsiung City 82446, Taiwan